Ekusetshenzisweni kwanamuhla kwezohwebo nezomuntu siqu, ukusetshenziswa kwamabhokisi e-acrylic kuyatholakala yonke indawo. Kusukela ekupakishweni okuhle kwezipho ezisezingeni eliphezulu kuya ekuboniseni nasekugcineni imikhiqizo ehlukahlukene ye-elekthronikhi, izimonyo, ubucwebe, nezinye izinto, amabhokisi e-acrylic abe yisisombululo esithandwayo sokupakisha nokubonisa izimboni eziningi ngenxa yokucaca kwawo okuhle, ukwakheka okuhle, kanye nokuqina okuphezulu. Njengoba kukhula ukuncintisana emakethe kanye nesidingo esikhulayo sabathengi sokwenza kube ngokwakho, isidingo samabhokisi e-acrylic enziwe ngokwezifiso naso sibonisa ukuthambekela okukhuphuka ngokushesha.

Ngokuphikisana nalesi simo semakethe, ukukhetha ukusebenza nomkhiqizi wamabhokisi e-acrylic angokwezifiso kubaluleke kakhulu futhi kunezinzuzo eziningi ezingaba khona kumabhizinisi nakubathengi. Abakhiqizi bomthombo banganikeza izinzuzo ezihlukile ezindaweni eziningana, okuhlanganisa ukulawulwa kwezindleko, ukuqinisekiswa kwekhwalithi, ukwenza ngokwezifiso, ukusebenza kahle kokukhiqiza, kanye nensizakalo yangemva kokuthengisa, ngaleyo ndlela kusiza amakhasimende ukuthi andise inani lemikhiqizo yawo, ahlangabezane nezidingo zemakethe ezahlukahlukene, futhi avelele emakethe yokuncintisana.

Okulandelayo, sizoxoxa ngokuningiliziwe ngezinzuzo ezahlukahlukene zokusebenza ne-Source Customised Acrylic Box Manufacturer.

1. Inzuzo Yezindleko Nezinzuzo

Inzuzo Yezindleko Zezinto Ezibalulekile:

Abakhiqizi bamabhokisi e-acrylic angokwezifiso bayakwazi ukusebenzisa ngokugcwele izinzuzo zokuthenga ngezinga ngenxa yobudlelwano besikhathi eside nobuzinzile ababusungule ngqo nabahlinzeki bezinto zokusetshenziswa ze-acrylic.

Ngokuvamile bathenga izinto zokusetshenziswa ze-acrylic ngobuningi obukhulu, okubanika ithuba eliqinile ezingxoxweni zamanani ezinto zokusetshenziswa futhi kubenze bakwazi ukuthola amanani okuthenga amahle kakhulu. Ngokuphambene nalokho, abakhiqizi abangebona abakhiqizi bavame ukudinga ukudlulela emazingeni amaningi abalamuli ukuze bathole izinto zokusetshenziswa, ngamunye ngesixhumanisi, intengo yezinto izokhuphuka ngokufanele, okuholela ekukhuleni okukhulu kwezindleko zezinto zokusetshenziswa zomkhiqizo wokugcina.

Isibonelo, umkhiqizi wamabhokisi e-acrylic atholakala ngomthombo uthenga izinkulungwane zamathani ezinto zokusetshenziswa ze-acrylic minyaka yonke, futhi ngokusayina inkontileka yokunikeza isikhathi eside nomhlinzeki, uyakwazi ukujabulela isaphulelo esingu-10% - 20% ngethani lezinto zokusetshenziswa uma kuqhathaniswa nentengo ejwayelekile yemakethe. Umkhiqizi ongeyena umthombo othenga izinto zokusetshenziswa ezifanayo kumlamuleli kungadingeka akhokhe u-20% - 30% ngaphezulu kunomkhiqizi womthombo.

Ukuthuthukisa Izindleko Zokwenza Ngokwezifiso:

Abakhiqizi bamabhokisi e-acrylic angokwezifiso bahlanganiswe kakhulu enkambisweni yokuklama nokukhiqiza ngokwezifiso, okunikeza isiqinisekiso esinamandla sokunciphisa izindleko zokwenza ngokwezifiso.

Ngamaqembu okuklama ochwepheshe kanye nemishini yokukhiqiza ethuthukisiwe, bangaqeda yonke inqubo ngempumelelo kusukela ekuqanjweni komklamo kuya ekukhiqizweni komkhiqizo oqediwe ngaphakathi.

Ngesikhathi sesigaba sokuklama esenziwe ngokwezifiso, ithimba labo lokuklama liyakwazi ukusebenza ngokushesha uhlelo lokuklama olunengqondo olusekelwe ezidingweni zamakhasimende kanye nezici zebhokisi le-acrylic, ligwema izindleko ezengeziwe ngenxa yokuxhumana okungekuhle kokuklama noma ukuguqulwa komklamo okuphindaphindiwe.

Enqubweni yokukhiqiza, umenzi webhokisi le-acrylic angalungisa uhlelo lokukhiqiza kanye nokwabiwa kwezinsiza ngokuvumelana nenani lama-oda kanye nezidingo zenqubo yokukhiqiza ukuze kufezwe ukusebenza kahle okukhulu kokukhiqiza. Isibonelo, ngosayizi omkhulu wama-oda enziwe ngokwezifiso, bangathatha imishini yokukhiqiza ezenzakalelayo ukuthuthukisa ukusebenza kahle kokukhiqiza nokunciphisa izindleko zokukhiqiza ngeyunithi ngayinye yomkhiqizo; futhi ngama-oda anezidingo ezikhethekile ezenziwe ngokwezifiso, bangenza futhi inqubo yokukhiqiza ihlangabezane nezidingo zamakhasimende ngaphandle kokwandisa izindleko ezinkulu.

Ngaphezu kwalokho, ukuze kukhuthazwe amakhasimende ukuthi enze ngokwezifiso ngobuningi, abakhiqizi bomthombo bavame ukwakha uchungechunge lwamasu akhethwayo, njengokunikeza amazinga ahlukene wezaphulelo ngokuya ngenani lama-oda. Kumakhasimende esikhathi eside, kunezikhuthazo ezengeziwe, njengezinhlelo zokukhiqiza eziza kuqala kanye nezinsizakalo zokuthuthukisa umklamo wamahhala. Zonke lezi zinyathelo zisiza amakhasimende ukuthi anciphise kakhulu izindleko zokwenza ngokwezifiso futhi athuthukise ukusebenza kahle kwemikhiqizo yawo.

2. Ukulawulwa Kwekhwalithi Nokuqinisekiswa

Ukulawulwa Kwezinto Ezingavuthiwe:

Abakhiqizi bamabhokisi e-acrylic angokwezifiso bayaqonda ukuthi ikhwalithi yezinto zokusetshenziswa inomthelela omkhulu kwikhwalithi yomkhiqizo wokugcina, ngakho-ke baqinile kakhulu ekukhetheni abahlinzeki bezinto zokusetshenziswa.

Bazokwenza ukuhlolwa okuphelele kwabaphakeli bezinto zokusetshenziswa ezingaba khona, okuhlanganisa iziqu zokukhiqiza zomphakeli, izinqubo zokukhiqiza, ukuzinza kwekhwalithi yomkhiqizo, ukuthobela imvelo, nezinye izici. Yilabo kuphela abaphakeli abadlula ukuhlolwa okuqinile abanethuba lokuba abalingani babo, futhi ngesikhathi senqubo yokubambisana, umenzi womthombo uzokwenza ukuvakasha njalo kwesiza kanye nokuhlolwa kwesampula yekhwalithi kubaphakeli ukuqinisekisa ukuthi ikhwalithi yezinto zokusetshenziswa ihlangabezana nezidingo njalo.

Isibonelo, umenzi webhokisi le-acrylic owaziwayo ekukhetheni abahlinzeki bezinto zokusetshenziswa ze-acrylic uzodinga abahlinzeki ukuthi banikeze izincazelo zenqubo yokukhiqiza ezinemininingwane, imibiko yokuhlola ikhwalithi, kanye nesitifiketi semvelo esifanele. Bazothumela njalo abahloli bekhwalithi abangochwepheshe endaweni yokukhiqiza yomhlinzeki ukuze baqondise futhi bahlole inqubo yokukhiqiza yezinto zokusetshenziswa.

Kuqoqo ngalinye lezinto zokusetshenziswa, ngaphambi kokungena esitshalweni sokukhiqiza, kuzokwenziwa ukuhlolwa kwekhwalithi okuqinile, ukuhlolwa kufaka phakathi ukucaca kwe-acrylic, ubulukhuni, ukumelana nesimo sezulu, kanye nezinye izinkomba ezibalulekile. Izinto zokusetshenziswa ezifanelekile kuphela ezizovunyelwa ukufakwa ekukhiqizweni, ngaleyo ndlela kuqinisekiswe ukuzinza kwekhwalithi yamabhokisi e-acrylic avela emthonjeni.

Ukuqapha Inqubo Yokukhiqiza:

Ngesikhathi sokukhiqizwa kwamabhokisi e-acrylic, abakhiqizi bomthombo basungule inqubo yokukhiqiza efanelekile kanye nohlelo lokuqapha ikhwalithi, futhi benza ukuhlolwa okuqinile kwekhwalithi kuzo zonke izici zenqubo, kusukela ekusikeni, nasekubumbeni kuya ekuhlanganisweni. Basebenzisa imishini yokukhiqiza ethuthukisiwe kanye nobuchwepheshe benqubo ukuqinisekisa ukuthi inqubo ngayinye yokukhiqiza ingahlangabezana nezidingo zokunemba okuphezulu kanye nekhwalithi.

Enqubweni yokusika, abakhiqizi bomthombo bavame ukusebenzisa imishini yokusika ye-laser enembile kakhulu, ekwazi ukusika amashidi e-acrylic ngokunembile futhi iqinisekise ukunemba okulinganayo kanye nokushelela kwemiphetho yamabhokisi.

Enqubweni yokubumba, kungakhathaliseki ukuthi kusetshenziswa inqubo yokubumba nge-thermoforming noma yokujova, amapharamitha enqubo, njengokushisa, ingcindezi, isikhathi, njll., azolawulwa ngokuqinile ukuqinisekisa ukuthi ibhokisi elibunjiwe linesimo esinembile kanye nesakhiwo esiqinile.

Enqubweni yokuhlanganisa, abasebenzi bazosebenza ngokwezinqubo zokusebenza eziqinile futhi basebenzise iglue esezingeni eliphezulu noma izinto zokuxhuma ukuqinisekisa ikhwalithi yokuhlanganisa ibhokisi.

Okwamanje, ngemva kwesixhumanisi ngasinye sokukhiqiza, kuzobekwa indawo yokuhlola ikhwalithi ukuze kwenziwe ukuhlolwa kwekhwalithi okuphelele ebhokisini ngalinye le-acrylic, ukuze uma izinkinga zekhwalithi sezitholakele, zilungiswe futhi zisingathwe ngesikhathi esifanele ukuze kugwenywe ukuthi imikhiqizo engafaneleki ingene esixhumanisweni esilandelayo sokukhiqiza.

Ngale nqubo yonke yokulawula ikhwalithi, umenzi womthombo angaqinisekisa ngempumelelo ikhwalithi yamabhokisi e-acrylic aqediwe futhi anikeze amakhasimende imikhiqizo esezingeni eliphezulu.

3. Ukuthuthukiswa Kwamakhono Okwenza Ngokwezifiso

Izinsiza Zokuklama kanye Nethimba:

Abakhiqizi bamabhokisi e-acrylic aklanyelwe ngendlela oyifisayo ngokuvamile banethimba lokuklama elingochwepheshe, futhi laba baklami banokuhlangenwe nakho okucebile embonini kanye namakhono okuklama ahlukahlukene. Abagcini nje ngokujwayelana nezici zezinto ze-acrylic kanye nobuchwepheshe bokucubungula futhi banganikeza ukudlala okugcwele izinzuzo ze-acrylic zokuklama ukuma kwebhokisi okuyingqayizivele nokuhle, kodwa futhi bayakwazi ukuqonda ngokujulile izidingo zamakhasimende kanye nezitayela zemakethe, ukuhlinzeka amakhasimende ngezixazululo zokuklama ezintsha nezenziwe ngezifiso.

Kungakhathaliseki ukuthi kuyisitayela sesimanje esilula nesinesitayela, isitayela sakudala esihle nesinobuhle, noma isitayela esinesihloko sokudala, ithimba lokuklama liyakwazi ukusisingatha kalula. Liyakwazi ukuhlinzeka ngezinsizakalo eziningi zokuklama, kusukela kumklamo womqondo kuya ekubumbeni kwe-3D, ngokusekelwe esithombeni somkhiqizo weklayenti, izici zomkhiqizo, izimo zokusetshenziswa, nolunye ulwazi.

Isibonelo, ebhokisini le-acrylic elenziwe ngokwezifiso lomkhiqizo wezimonyo, ithimba lokuklama lingahlanganisa ilogo yomkhiqizo, imibala, kanye nezici zomkhiqizo ukuze lidale ibhokisi elinezimo ezibucayi kanye nokuqashelwa komkhiqizo okuqinile, okudonsela ukunaka kwabathengi futhi kuthuthukise inani elengeziwe lomkhiqizo ngezinto zomklamo ezihlukile.

Ukulungiswa Kokukhiqiza Okuguquguqukayo:

Njengoba abakhiqizi bamabhokisi e-acrylic ayisisekelo benokuzimela okuphezulu kanye nokuguquguquka enqubweni yokukhiqiza kanye nokwabiwa kwezinsiza, bayakwazi ukuphendula ngokushesha ezinguqukweni zama-oda ngokwezifiso noma izidingo ezikhethekile ezivela kumakhasimende futhi balungise izinhlelo zokukhiqiza futhi basebenzise amapharamitha ngesikhathi esifanele. Uma bebhekene namabhokisi e-acrylic aklanyelwe izimboni ezahlukene kanye nokusetshenziswa, bayakwazi ukulungisa ngokushesha imishini yabo yokukhiqiza kanye nezinqubo ukuqinisekisa ukukhiqizwa okubushelelezi kwemikhiqizo yabo.

Isibonelo, lapho ikhasimende licela ibhokisi le-acrylic elenziwe ngokwezifiso elinosayizi okhethekile nesimo sokubonisa umkhiqizo we-elekthronikhi osezingeni eliphezulu, umenzi womthombo angahlela ngokushesha ochwepheshe ukuthi balungise imishini yokukhiqiza futhi balungise amapharamitha enqubo yokusika nokubumba ukuqinisekisa ukuthi bangakhiqiza ibhokisi elihlangabezana nezidingo zekhasimende.

Ngesikhathi esifanayo, bangangeza nezici ezikhethekile noma imihlobiso ebhokisini ngokwezidingo zamakhasimende, njengemiphumela yokukhanya eyakhelwe ngaphakathi, izinqubo ezikhethekile zokwelashwa kwendawo, njll., ukuze bathuthukise kakhulu ukwenziwa ngokwezifiso kanye nokwehlukaniswa komkhiqizo.

Leli khono lokulungisa ukukhiqiza eliguquguqukayo lenza abakhiqizi bomthombo bakwazi ukuhlangabezana kangcono nezidingo zokwenza ngokwezifiso zamakhasimende abo ezihlukahluka kakhulu futhi ezenziwe ngokwezifiso futhi babanikeze izinsizakalo ezinakekelayo kakhudlwana.

4. Ukusebenza Kahle Kokukhiqiza kanye Nokulethwa Ngesikhathi

Imishini Yokukhiqiza Ethuthukisiwe:

Ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo, abakhiqizi bamabhokisi e-acrylic angokwezifiso bavame ukutshala imali eningi ezindaweni zokukhiqiza ezithuthukisiwe. Le mishini ihlanganisa imishini yokusika nge-laser, imishini yokuqopha ngokunemba, amaphrinta e-UV, njalo njalo.

Umshini wokusika nge-laser uyithuluzi elibalulekile lokukhiqiza, isimiso sawo sokusebenza siwukukhipha imisebe ye-laser enamandla aphezulu, ukuze ishidi le-acrylic lincibilike noma liphele ngokushesha, ukuze kufezwe ukusika okunembile. Lolu hlobo lokusika lunokunemba okuphezulu kakhulu, futhi iphutha lingalawulwa ngaphakathi kobubanzi obuncane kakhulu, okuqinisekisa ukuhambisana nokunemba kosayizi wezingxenye zebhokisi. Ngesikhathi esifanayo, ijubane lokusika liyashesha, lifinyeza kakhulu umjikelezo wokukhiqiza, futhi unqenqema lokusika lubushelelezi futhi lulingana, ngaphandle kokucubungula kwesibili, okuthuthukisa ngempumelelo izinga lokusetshenziswa kwezinto futhi kunciphisa imfucuza.

Ngakolunye uhlangothi, umshini wokuqopha ngokunemba ugxile ekuqopheni kahle ezintweni ze-acrylic. Uhlonyiswe nge-spindle enembile kakhulu kanye nohlelo lokulawula oluthuthukisiwe, ungaqopha ngokuphelele amaphethini ahlukahlukene ayinkimbinkimbi, ukuthungwa okubucayi, kanye nama-logo omkhiqizo acacile ebusweni bebhokisi ngokuya ngohlelo oluhleliwe. Kungakhathaliseki ukuthi imigqa ebucayi noma imiphumela yokukhululeka okujulile, umshini wokuqopha ngokunemba ungawanikeza ubuciko obuhle kakhulu, unikeze amabhokisi e-acrylic inani eliyingqayizivele lobuciko kanye nokuthungwa okuphezulu, okwenza avelele emakethe.

Iphrinta ye-UV nayo ingenye yemishini ebalulekile. Le phrinta iyakwazi ukufeza imiphumela yokuphrinta enesinqumo esiphezulu, enemibala eminingi, kungakhathaliseki ukuthi imibala ecacile nekhanyayo, imibala yemvelo nebushelelezi, noma izithombe ezingokoqobo nezicacile, zonke ezingavezwa ngokunembile ebhokisini. Lokhu akugcini nje ngokuhlangabezana nezidingo ezahlukahlukene zamakhasimende zomklamo wokubukeka owenzelwe wena futhi owenziwe ngokwezifiso, kodwa futhi kuqinisekisa ukuthi amaphethini aphrintiwe anokumelana okuhle nokuguguleka nokuqina, futhi ahlala emuhle futhi ephilile isikhathi eside.

Ukuphathwa Kokukhiqiza Okuphumelelayo:

Ngaphezu kokuba nemishini yokukhiqiza ethuthukisiwe, abakhiqizi bomthombo basungule nohlelo lokuphatha ukukhiqiza olusebenzayo. Ngokuhlela nokubeka isimiso sokukhiqiza ngokwesayensi, bahlela imisebenzi yokukhiqiza kanye nokwabiwa kwezinsiza ukuqinisekisa ukuthi isixhumanisi ngasinye sokukhiqiza singaxhunyaniswa eduze futhi senziwe ngendlela ehlelekile. Enkambisweni yokuhlela ukukhiqiza, bazocabangela ngokugcwele inani lama-oda, isikhathi sokulethwa, ubunzima benqubo yokukhiqiza, kanye nezinye izici zokuthuthukisa uhlelo lokukhiqiza olufanele.

Enkambisweni yokwenza i-oda, bazoqapha inqubekela phambili yokukhiqiza ngesikhathi sangempela, futhi bathole futhi baxazulule izinkinga enkambisweni yokukhiqiza ngesikhathi. Isibonelo, uma kukhona ukwehluleka kwemishini noma ukuntuleka kwezinto zokusetshenziswa enkambisweni yokukhiqiza, uhlelo lokuphatha ukukhiqiza lungasabela ngokushesha ngokulungisa uhlelo lokukhiqiza nokuthumela eminye imishini noma izinto zokusetshenziswa ukuqinisekisa ukuthi ukukhiqizwa akuthinteki.

Uma ephendula ama-oda aphuthumayo noma amazinga aphezulu e-oda, umenzi womthombo uyakwazi ukunikeza amandla akhe okusebenzisa izinsiza, ngokukhiqiza isikhathi esengeziwe, ukwanda kwesikhashana kwabasebenzi bokukhiqiza, noma ukulungisa ukusetshenziswa kwemishini yokukhiqiza, njll., ukuze kuhlangatshezwane nezidingo zokulethwa kwekhasimende. Lolu hlelo lokuphatha ukukhiqiza olusebenzayo luvumela umenzi womthombo ukuthi afinyelele ukulethwa ngesikhathi futhi andise ukwaneliseka kwamakhasimende ngenkathi egcina ikhwalithi yomkhiqizo.

5. Isevisi Yangemva Kokuthengisa Nokubambisana Kwesikhathi Eside

Uhlelo Lwesiqinisekiso Ngemva Kokuthengisa:

Uhlelo lokuvikela ngemuva kokuthengisa olwakhiwe ngumkhiqizi wamabhokisi e-acrylic aklanyelwe wena luhlose ukuhlinzeka amakhasimende ngokusekelwa kwesevisi okuzungezile, okusebenzayo, nokukhathalelayo. Lapho amakhasimende ephendula ngezinkinga zomkhiqizo, ithimba lenkonzo yamakhasimende elingochwepheshe lizophendula ngokushesha, lixhumane namakhasimende okokuqala, liqonde isimo ngokuningiliziwe, futhi lirekhode. Ngemuva kwalokho, ikhambi lizonikezwa ezinsukwini ezingu-1-2.

Ngesikhathi esifanayo, bazophinde bavakashele amakhasimende njalo ukuze baqoqe ulwazi kanye neziphakamiso zokuthuthukisa, futhi bathuthukise njalo uhlelo lwangemva kokuthengisa, ukuze bathuthukise ukwaneliseka kwamakhasimende kanye nokwethembeka ngesimo sengqondo sobungcweti nesinesibopho, futhi bakhe isithombe esihle somkhiqizo.

Ukwakha Ubudlelwano Besikhathi Eside:

Ukusungula ubambiswano lwesikhathi eside nomkhiqizi wamabhokisi e-acrylic angokwezifiso kubaluleke kakhulu kumakhasimende.

Okokuqala, ukubambisana kwesikhathi eside kunganikeza amakhasimende ukunikezwa kwemikhiqizo okuzinzile. Umkhiqizi womthombo, ngenxa yobukhulu bokukhiqiza kanye nezinzuzo zezinsiza, angaqinisekisa ukuthi amakhasimende adinga ukuhlinzeka ngemikhiqizo yebhokisi le-acrylic edingekayo ngokushesha, ukuze agweme ukuphazamiseka kokunikezwa okuthinta uhlelo lokukhiqiza nokuthengisa lwekhasimende.

Okwesibili, ukubambisana kwesikhathi eside kusiza amakhasimende ukuthi anciphise izindleko. Njengoba isikhathi sokubambisana siqhubeka, ukwethembana phakathi komkhiqizi womthombo kanye nekhasimende kuyanda, futhi izinhlangothi zombili zingakwazi ukwenza izingxoxo ezijulile kanye nokwenza ngcono ngokwezidingo zamanani kanye nokwenza ngokwezifiso. Umkhiqizi womthombo angase akwazi ukunikeza amanani amahle kakhulu, izinsizakalo zokwenza ngokwezifiso eziguquguqukayo, kanye namalungiselelo okukhiqiza abaluleke kakhulu kumakhasimende esikhathi eside, ngaleyo ndlela abasize ukunciphisa izindleko zabo zokuthenga nezokusebenza.

Ngaphezu kwalokho, ubambiswano lwesikhathi eside lungasiza ukubambisana ekusungulweni kwezobuchwepheshe kanye nokuthuthukiswa komkhiqizo. Umkhiqizi womthombo anganikeza amakhasimende imikhiqizo encintisana kakhulu ngokuthuthukisa njalo ukwakheka komkhiqizo kanye nezinqubo zokukhiqiza ngokusekelwe kwimpendulo yemakethe yamakhasimende kanye nezidingo ezishintshayo. Ngesikhathi esifanayo, ikhasimende lingasebenzisa amakhono ocwaningo nokuthuthukiswa komkhiqizi womthombo ukuthuthukisa izinhlelo zokusebenza zomkhiqizo omusha nokwandisa isabelo semakethe.

Ngalobu budlelwano besikhathi eside, izinhlangothi zombili zingabelana ngezinsiza, zigcwalise amandla omunye nomunye, futhi ziphendule ngokubambisana ezinguqukweni zemakethe kanye nezinselele zokuncintisana ukuze kufezwe intuthuko esimeme.

Umkhiqizi Webhokisi Le-Acrylic Elihle Kakhulu LaseShayina

I-Jayi Acrylic Industry Limited

Jayi, njengomholiumenzi womkhiqizo we-acryliceShayina, inamandla amakhulu emkhakheni we-amabhokisi e-acrylic ngokwezifiso.

Le fektri yasungulwa ngo-2004 futhi ineminyaka ecishe ibe ngu-20 yesipiliyoni ekukhiqizeni okwenziwe ngokwezifiso.

Le fektri inendawo yefektri eyakhelwe ngokwayo engamamitha-skwele ayi-10,000, indawo yehhovisi engamamitha-skwele angama-500, kanye nabasebenzi abangaphezu kwe-100.

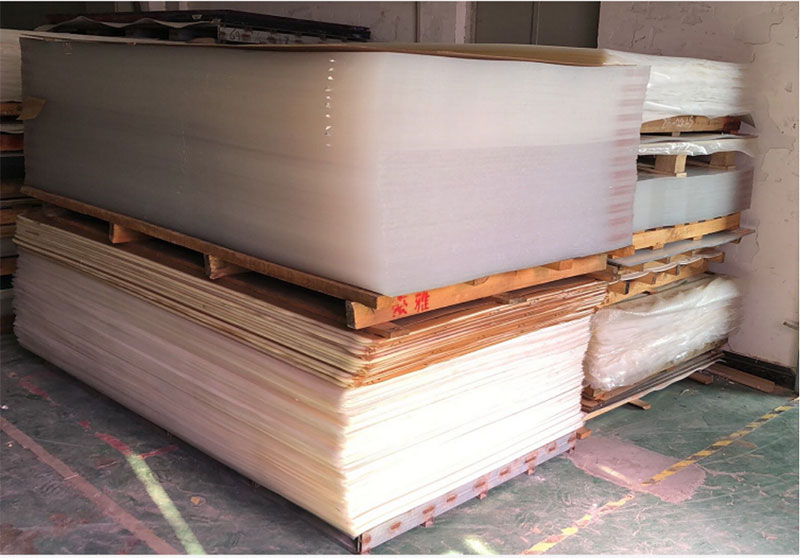

Njengamanje, ifektri inemigqa eminingana yokukhiqiza, ifakwe imishini yokusika nge-laser, imishini yokuqopha ye-CNC, amaphrinta e-UV, neminye imishini yobungcweti, amasethi angaphezu kwama-90, zonke izinqubo ziqedwa yifektri uqobo, futhi umkhiqizo waminyaka yonke wazo zonke izinhlobo zamabhokisi e-acrylic ungaphezu kwezingcezu ezingama-500,000.

Isiphetho

Ukusebenza nabakhiqizi bamabhokisi e-acrylic angokwezifiso kunezinzuzo eziningana ezibalulekile.

Ngokuphathelene nokusebenza kahle kwezindleko, inganikeza amakhasimende amanani ancintisanayo ngokusebenzisa izinzuzo zezindleko ezibonakalayo kanye nokwenza ngcono izindleko ngokwezifiso;

Ngokuphathelene nokulawulwa kwekhwalithi nokuqinisekiswa, ngokulawulwa okuqinile kwezinto zokusetshenziswa kanye nokuphathwa okuphelele kwenqubo yokukhiqiza, ukuqinisekisa ikhwalithi ephezulu yemikhiqizo;

Ngokuphathelene nokuthuthukiswa kwamakhono okwenza ngokwezifiso, ithimba lokuklama lochwepheshe kanye nokulungiswa kokukhiqiza okuguquguqukayo kungahlangabezana nezidingo ezahlukahlukene neziqondene nomuntu ngamunye zamakhasimende;

Ngokuphathelene nokusebenza kahle kokukhiqiza kanye nokulethwa ngesikhathi, izikhungo zokukhiqiza ezithuthukisiwe kanye nokuphathwa kokukhiqiza okuphumelelayo kungafeza ukukhiqizwa okusheshayo kanye nokulethwa ngesikhathi;

Ngokuphathelene nenkonzo yangemva kokuthengisa kanye nokubambisana kwesikhathi eside, uhlelo lokuvikela ngemuva kokuthengisa oluphelele kanye nobambiswano lwesikhathi eside lungathuthukisa ukwaneliseka kwamakhasimende kanye nokwethembeka, futhi luzuze kokubili kanye nesimo esizuzisa wonke umuntu kuzo zombili izinhlangothi.

Ngakho-ke, kumabhizinisi nakubathengi ngabanye abanesidingo samabhokisi e-acrylic enziwe ngokwezifiso, lapho bekhetha umlingani, kufanele kunikezwe kuqala ukubambisana nomkhiqizi wamabhokisi e-acrylic enziwe ngokwezifiso umthombo. Lokhu ngeke nje kukwazi ukuthola imikhiqizo nezinsizakalo ezisezingeni eliphezulu, kodwa futhi kuzokwazi ukuthatha isikhundla esihle emncintiswaneni wemakethe, ukufeza izinhloso zabo zebhizinisi nokukhulisa inani lomkhiqizo.

Amanye Amacala Ebhokisi Le-Acrylic Elakhelwe Ngokwezifiso:

Uma usebhizinisini, ungathanda:

Isikhathi sokuthunyelwe: Novemba-29-2024