Amathreyi e-Acrylicsezithandwa kakhulu ezindaweni zokuhlala nezebhizinisi ngenxa yokubukeka kwazo okubushelelezi, ukuqina, kanye nokuguquguquka kwazo.

Kungakhathaliseki ukuthi kusetshenziswa njengamathreyi okukhonza endaweni yokudlela esezingeni eliphezulu, ukuhlela amathreyi esitolo sezinto zokunethezeka, noma amathreyi okuhlobisa ekhaya lesimanje, amathreyi e-acrylic enziwe ngokwezifiso anikeza inhlanganisela eyingqayizivele yokusebenza kanye nokukhanga kobuhle.

Kodwa wake wazibuza ukuthi yini edingekayo ekudaleni lezi zingcezu ezenziwe ngokwezifiso? Kulo mhlahlandlela ophelele, sizokuhambisa yonke inqubo yokukhiqiza ithreyi ye-acrylic eyenziwe ngokwezifiso, kusukela emcabangweni wokuqala wokuklama kuya ekulethweni kokugcina emnyango wakho.

1. Ukubonisana Ngokuklama Nokucabanga

Uhambo lwethreyi ye-acrylic eyenziwe ngokwezifiso luqala ngengxoxo.Ukubonisana ngokuklama kuyisinyathelo sokuqala esibalulekilelapho umbono weklayenti uhlangabezana khona nolwazi lomenzi.

Phakathi nalesi sigaba, amakhasimende angabelana ngemibono yawo, okuhlanganisa ubukhulu, ukuma, umbala, nanoma yiziphi izici ezithile azifunayo, njengezingxenye, izibambo, noma ama-logo aqoshiwe.

Abakhiqizi bavame ukuhlinzeka ngamathempulethi okuklama noma basebenze namakhasimende ukudala uhlelo oluhlelekile besebenzisa isofthiwe yokuklama esekelwa yikhompyutha (i-CAD).

Le software ivumela izilinganiso ezinembile kanye nokuboniswa kwe-3D, okusiza amakhasimende ukubona ngeso lengqondo umkhiqizo wokugcina ngaphambi kokuba kuqale ukukhiqizwa.

Futhi yisigaba lapho kunqunywa khona ubukhulu bezinto—i-acrylic ejiyile (3mm kuya ku-10mm) ilungele ukusetshenziswa okunzima, kuyilapho amashidi amancane (1mm kuya ku-2mm) esebenza kahle kumathileyi okuhlobisa alula.

2. Ukukhetha Izinto: Ukukhetha i-Acrylic Efanele

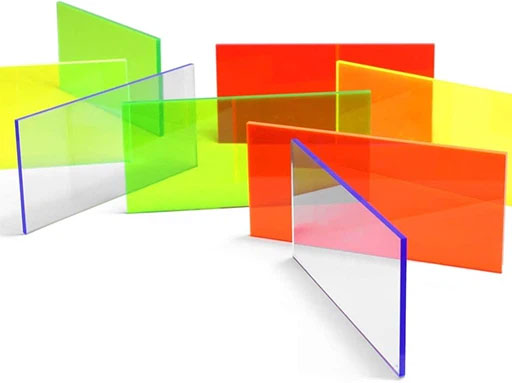

I-Acrylic, eyaziwa nangokuthi i-PMMA (polymethyl methacrylate), iza ngezindlela ezahlukene, futhi ukukhetha uhlobo olufanele kuyisihluthulelo ekusebenzeni nasekubukekeni kwethreyi.

I-acrylic ecacile iyona ethandwa kakhulu ngenxa yokubonakala kwayo okufana nengilazi, kodwa i-acrylic enemibala, i-acrylic eqandisiwe, kanye ne-acrylic ehlanganisiwe iyatholakala ngemiklamo eyingqayizivele.

Abakhiqizi bathola amashidi e-acrylic asezingeni eliphezulu kubaphakeli abathembekile ukuqinisekisa ukuqina nokuqina.

Ukumelana kwe-UV kwale nto kungenye into ebalulekile, ikakhulukazi kumathileyi asetshenziswa ngaphandle, njengoba kuvimbela ukuphuzi ngokuhamba kwesikhathi.

Ngaphezu kwalokho, amanye amakhasimende akhetha ukusebenzisa i-acrylic ephinde yasetshenziswa ukuze ivumelane nemikhuba enobungani nemvelo, okuwumkhuba okhulayo embonini yokukhiqiza ngokwezifiso.

3. Ukuhlola Umklamo: Ukuhlola Umklamo

Ngaphambi kokuthuthela ekukhiqizweni ngobuningi, ukudala iphrothokholi kubalulekile ekulungiseni umklamo nasekubhekaneni nanoma yiziphi izinkinga ezingaba khona.

Ukubhala ngemifanekiso kuvumela amakhasimende ukuthi ahlole usayizi wethreyi ye-acrylic, ukuma kwayo, kanye nokuphela kwayo, enze izinguquko uma kudingeka.

Besebenzisa umklamo we-CAD, abakhiqizi bangaphrinta i-prototype ye-3D noma basike inqwaba encane ye-acrylic besebenzisa i-laser cutter ukuze bathole isithombe esinembile.

Lesi sinyathelo sibalulekile ekuqinisekiseni ukuthi umkhiqizo wokugcina uhlangabezana nokulindelwe yiklayenti, kungakhathaliseki ukuthi yindawo efanelekile noma unqenqema olucwebezelisiwe kahle.

4. Ukusika Nokubumba I-Acrylic

Uma umklamo usuqediwe, inqubo yokukhiqiza iqhubekela ekusikeni nasekubumbeni amashidi e-acrylic.

Ukusika nge-laser kuyindlela ekhethwayo yamathileyi e-acrylic enziwe ngokwezifiso ngenxa yokunemba kwayo kanye nekhono layo lokudala izimo eziyinkimbinkimbi.

Umsiki we-laser ulandela umklamo we-CAD, usika i-acrylic ngokungcola okuncane kanye nemiphetho ebushelelezi.

Ukuze uthole izimo eziyinkimbinkimbi noma imiphetho egobile, abakhiqizi bangasebenzisa ama-router e-CNC (Computer Numerical Control), angabumba i-acrylic ngokunemba okuphezulu.

Lesi sinyathelo sibalulekile ekuqinisekiseni ukuthi zonke izingxenye zethreyi—njengesisekelo nezinhlangothi—zihlangana kahle ngesikhathi sokuhlanganiswa.

5. Ukupholisha Umphetho: Ukufeza Ukuqeda Okubushelelezi

Imiphetho yethreyi ye-acrylic eluhlaza ingaba lukhuni futhi ingacaci, ngakho-ke ukupholisha kuyadingeka ukuze kufezwe ukuphela okucwebezelayo nokusobala. Kunezindlela eziningana zokupholisha imiphetho ye-acrylic:

Ukupholisha ilangabi:Indlela esheshayo nephumelelayo lapho ilangabi elilawulwayo lincibilikisa khona unqenqema kancane, okwenza indawo ebushelelezi necacile.

Ukupholisa: Ukusebenzisa isondo elijikelezayo elinamakhompiyutha okupholisha ukuze kube bushelelezi unqenqema, okulungele amashidi e-acrylic ajiyile.

Ukupholisha okudlidlizayo:Ifanele ukukhiqizwa ngobuningi, le ndlela isebenzisa umshini onemidiya yokukhuhla ukuze ipholishe izingcezu eziningi ngesikhathi esisodwa.

Unqenqema olucwebezelisiwe kahle alugcini nje ngokuthuthukisa ukubukeka kwethileyi kodwa futhi lususa noma yikuphi ukucija, okwenza kube kuphephile ukuliphatha.

6. Ukuhlanganisa: Ukuhlanganisa Konke

Kumathreyi e-acrylic anezinhlangothi, izingxenye, noma izibambo, ukuhlanganiswa kuyisinyathelo esilandelayo. Abakhiqizi basebenzisa usimende we-acrylic (ingcina esekelwe ku-solvent) ukuhlanganisa izingcezu ndawonye.

I-samente isebenza ngokuncibilikisa ubuso be-acrylic, idale isibopho esiqinile nesingenamthungo uma somile.

Ukuqondanisa ngokucophelela kubalulekile ngesikhathi sokuhlanganiswa ukuqinisekisa ukuthi ithileyi lilingana futhi liqinile ngokwesakhiwo. Ama-clamp angasetshenziswa ukubamba izingcezu endaweni yazo ngenkathi usimende uqina, okuvame ukuthatha amahora ambalwa.

Ngobaamathreyi e-acrylic anezibambo, imigodi iyabholwa (uma ingakasikwa kakade ngesikhathi sokwakheka), futhi izibambo zinamathiselwa kusetshenziswa izikulufo noma ingcina, kuye ngomklamo.

7. Ukwenza ngokwezifiso: Ukwengeza ama-Logo, Imibala, kanye nokuQeda

Ukwenza ngokwezifiso yikho okwenza ithreyi ngayinye ye-acrylic ibe ngeyahlukile. Kunezindlela eziningana zokwenza ithreyi ibe ngeyakho:

Ukuqopha:Ukuqopha nge-laser kungangeza ama-logo, umbhalo, noma amaphethini ebusweni, okudala umklamo ohlala njalo nosezingeni eliphezulu.

Ukuphrinta:Ukuphrinta kwe-UV kuvumela imiklamo enemibala egcwele ku-acrylic, okulungele ihluzo ezigqamile noma ama-logo omkhiqizo.

Umdwebo:Kumathileyi anombala, upende we-acrylic noma upende wokufutha ungasetshenziswa ebusweni, kanye nopende ocacile owengeziwe ukuze uvikeleke.

Ukuqandisa:Indlela yokuqhuma ngesihlabathi idala ukuphela okungacacile, okungacacile engxenyeni noma kuyo yonke ithileyi, okwengeza ukuthinta kobuhle.

Lezi zinketho zokwenza ngokwezifiso zisiza amakhasimende ukuthi adale amathreyi ahambisana nobunikazi bomkhiqizo wawo noma isitayela somuntu siqu.

8. Ukulawulwa Kwekhwalithi: Ukuqinisekisa Ubuhle

Ngaphambi kokupakisha, ithreyi ngayinye ye-acrylic eyenziwe ngokwezifiso ihlolwa ngokuqinile ngokulawulwa kwekhwalithi. Abahloli bayahlola:

•Ubukhulu obufanele kanye nesimo

•Imiphetho ebushelelezi, ecwebezelayo

•Izibopho eziqinile, ezingenamthungo kumathileyi ahlanganisiwe

•Ukuqoshwa noma ukuphrinta okucacile nokunembile

•Akukho ukuklwebheka, amabhamuza, noma amaphutha ku-acrylic

Noma yimaphi amathreyi e-acrylic angahlangabezani nezindinganiso zekhwalithi ayalungiswa kabusha noma alahlwe, okuqinisekisa ukuthi imikhiqizo engcono kakhulu kuphela efinyelela iklayenti.

9. Ukupakisha Nokuthumela: Ukuletha Ngokucophelela

I-Acrylic ihlala isikhathi eside kodwa ingaklwebheka kalula, ngakho-ke ukupakishwa okufanele kubalulekile.

Amathreyi e-Acrylic asongwa ngefilimu evikelayo noma iphepha lezicubu ukuvimbela imihuzuko bese efakwa emabhokisini aqinile ane-padding ukugwema umonakalo ngesikhathi sokuthutha.

Abakhiqizi basebenzisana nabalingani bokuthumela abathembekile ukuqinisekisa ukulethwa ngesikhathi, kungaba ukulethwa kwendawo noma ukuthunyelwa kwamanye amazwe.

Ulwazi lokulandelela lunikezwa amakhasimende, okubavumela ukuthi baqaphele inqubekela phambili ye-oda labo kuze kube yilapho lifika.

10. Ukusekelwa Ngemva Kokulethwa: Ukuqinisekisa Ukwaneliseka

Inqubo yokukhiqiza ayipheli ngokulethwa.

Abakhiqizi abadumile banikeza ukwesekwa ngemva kokulethwa, bebhekana nanoma yiziphi izinkinga ezingase ziphakame futhi banikeze imiyalelo yokunakekela ukusiza amakhasimende agcine amathreyi awo e-acrylic.

Ukunakekelwa okufanele—njengokuhlanza ngendwangu ethambile nensipho ethambile—kungandisa isikhathi sokuphila kwethileyi, kuligcine libukeka lisha iminyaka eminingi ezayo.

Isiphetho

Ukudala ithreyi ye-acrylic eyenziwe ngokwezifiso kuyinqubo eningiliziwe ehlanganisa ubuchwepheshe bokuklama, amasu okukhiqiza athuthukile, kanye nokugxila ekhwalithini.

Kusukela ekubonisaneni kokuqala kuya ekulethweni kokugcina, isinyathelo ngasinye senziwa ngokucophelela ukuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nombono weklayenti futhi udlula lokho abakulindele.

Kungakhathaliseki ukuthi udinga ithileyi elenziwe ngokwezifiso lebhizinisi lakho noma isipho esiyingqayizivele, ukuqonda le nqubo kungakusiza ukuthi wenze izinqumo ezinolwazi futhi uqonde ubuciko obusemuva kwengxenye ngayinye.

Imibuzo Evame Ukubuzwa (Imibuzo Evame Ukubuzwa) Mayelana Nama-Acrylic Tray Angokwezifiso

Uyini Umehluko Phakathi Kwama-Acrylic nama-Glass Tray?

Amathileyi e-Acrylic alula, awaphuki, futhi ahlala isikhathi eside kunengilazi, okwenza afanele ukusetshenziswa nsuku zonke.

Zinikeza ukucaca okufana nengilazi kodwa kulula ukuzenza ngemibala, ukuqoshwa, noma ukuma.

I-Acrylic iphinde imelane nokuphuzi kwe-UV kangcono kunengilazi, yize ingaklwebheka kalula uma inganakekelwa kahle.

Kuthatha Isikhathi Esingakanani Ukukhiqiza Ithreyi Ye-Acrylic Eyenziwe Ngokwezifiso?

Isikhathi sesikhathi siyahlukahluka ngokuya ngobunzima bomklamo.

Imiklamo elula enosayizi ojwayelekile ithatha izinsuku zebhizinisi ezi-5-7, okuhlanganisa ukuvunyelwa komklamo kanye nokukhiqizwa kwawo.

Imiklamo eyinkimbinkimbi enezicucu eziyinkimbinkimbi, izingxenye eziningi, noma ukuqoshwa okwenziwe ngokwezifiso kungathatha izinsuku eziyi-10-14, okubalwa ukwenziwa kweprototype nokulungiswa.

Ukuthunyelwa kwenezela izinsuku ezingu-2-5, kuye ngendawo.

Ingabe Amathreyi E-Acrylic Angasetshenziswa Ngaphandle?

Yebo, kodwa khetha i-acrylic engamelani ne-UV ukuze uvimbele ukuphuzi elangeni.

Gwema amazinga okushisa aphezulu kakhulu, njengoba i-acrylic ingagoba ngaphezu kuka-160°F (70°C).

Amathileyi angaphandle alungele ukusetshenziswa emapatio noma eceleni kwechibi—awaphuki, alula, futhi kulula ukuwahlanza ngensipho namanzi athambile.

Yiziphi izinketho zokwenza ngokwezifiso ezitholakalayo zama-Acrylic Trays?

Izinketho zifaka phakathi ukuqoshwa nge-laser (ama-logo, umbhalo), ukuphrinta kwe-UV (imiklamo enemibala egcwele), ukuqandisa (ukuqedwa okucwebezelayo), kanye nobukhulu/ubume obungokwezifiso.

Ungangeza izingxenye, izibambo, noma amashidi e-acrylic anombala.

Abakhiqizi bavame ukunikeza ukubuka kuqala kwe-CAD ukuqinisekisa ukuthi umklamo uhambisana nombono wakho ngaphambi kokukhiqiza.

Ngingayigcina Kanjani Ithreyi Ye-Acrylic Ukuze Ihlale Ibukeka Intsha?

Hlanza ngendwangu ethambile nensipho ethambile—gwema izihlanzi ezikhuhlayo noma izihlanzi ezibangela imihuzuko.

Uma unamabala aqinile, sebenzisa i-polish yepulasitiki.

Gcina kude nezinto ezibukhali, futhi ugweme ukubeka izinto ezisindayo phezulu ukuze ugweme ukugoba.

Ngokunakekelwa okufanele, amathreyi e-acrylic angahlala iminyaka eminingi ngaphandle kokulahlekelwa ukukhanya kwawo.

I-Jaiyacrylic: Umkhiqizi Wakho Ohamba Phambili Wethreyi Ye-Acrylic Eyenziwe Ngokwezifiso YaseShayina

I-Jayi acrylicungumkhiqizi wethreyi ye-acrylic ochwepheshe eShayi. Izixazululo zethreyi ye-acrylic zikaJayi zenzelwe ukujabulisa amakhasimende nokwethula izinto ngendlela ekhangayo kakhulu. Ifektri yethu inezitifiketi ze-ISO9001 kanye ne-SEDEX, okuqinisekisa ikhwalithi ephezulu kanye nemikhuba yokukhiqiza enokuziphatha okuhle. Njengoba sineminyaka engaphezu kwengu-20 yesipiliyoni ngokubambisana nemikhiqizo ehamba phambili, siyaqonda ngokugcwele ukubaluleka kokuklama amathreyi e-acrylic akhulisa ukubonakala kwento futhi akhuthaze ukwaneliseka kokusetshenziswa.

Ncoma Ukufundwa

Ungase Uthande Neminye Imikhiqizo Ye-Acrylic Eyenziwe Ngokwezifiso

Isikhathi sokuthunyelwe: Agasti-13-2025