Ithreyi ye-Acrylic uhlobo lohlobo lwethreyi olusetshenziswa kabanzi kuzo zonke izindlela zokuphila. Ukucaca kwayo okuhlukile, ukuqina, kanye nokwenza ngokwezifiso kuyenza ithandwe emakethe. Isidingo semakethe yokwenza ngokwezifiso ithreyi ye-acrylic siyakhula. Izimboni ezahlukene kanye nezinhlelo zokusebenza zinezidingo zazo zobukhulu, ukuma, umsebenzi, kanye nekhwalithi yamathreyi. Amathreyi ajwayelekile endabuko awakwazi ukuhlangabezana ngokugcwele nalezi zidingo, ngakho-ke ukwenza ngokwezifiso amathreyi e-acrylic kuba okubaluleke kakhulu. Ngokwenza ngokwezifiso amathreyi e-acrylic, amabhizinisi angathola izixazululo zamathreyi ezihambisana nemikhiqizo yawo, izinqubo zokusebenza, kanye nesithombe somkhiqizo, athuthukise ukusebenza kahle kwempahla, anciphise ukulahlekelwa, futhi abonise isithombe sobungcweti.

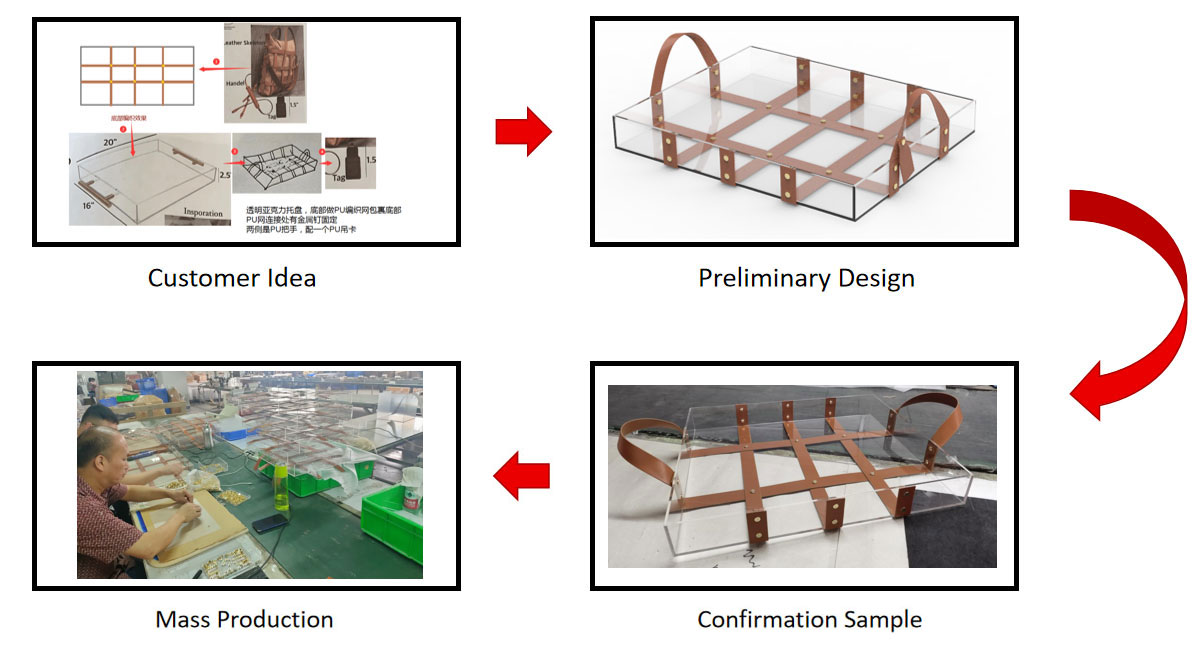

Isihloko salesi sihloko yinqubo yokwenza ngokwezifiso ithreyi ye-acrylic. Sizokwethula izigaba ezahlukahlukene kanye nezixhumanisi zokwenza ngokwezifiso ithreyi ye-acrylic ngokuningiliziwe, okuhlanganisa ukuhlaziywa kwesidingo kanye nokuxhumana, isigaba sokuklama, ukukhethwa kwezinto kanye nokucubungula, ukukhiqizwa kanye nokuhlanganiswa, njll. Ngokubheka ngokujulile lezi zinqubo, abafundi bazofunda ukuthi bangenza kanjani ngokwezifiso amathreyi e-acrylic asezingeni eliphezulu ngokwezidingo zomuntu ngamunye.

Okulandelayo, sizohlola inqubo yokwenza ngokwezifiso ithreyi le-acrylic ngokujulile ukuze sisize abafundi baqonde kangcono futhi basebenzise ulwazi kulo mkhakha wobungcweti.

Inqubo Yokwenza Ngokwezifiso Yethreyi Ye-Acrylic

A) Ukuhlaziywa Kwezidingo Nokuxhumana

Enkambisweni yokwenza ngokwezifiso ithreyi le-acrylic, ukuhlaziywa kwesidingo, kanye nokuxhumana kuyizinyathelo ezibaluleke kakhulu. Kuhilela ukuxhumana okuphumelelayo nokuqondana phakathi kwamakhasimende nabakhiqizi bamathreyi e-acrylic ukuqinisekisa ukuqonda okuphelele kanye nokuqonda okunembile kwezidingo zamakhasimende.

Inqubo yokuxhumana phakathi kwekhasimende nomkhiqizi:

Ukubonisana Kokuqala

Amakhasimende aqala ngokuxhumana nomkhiqizi ukuze aveze izidingo nezinhloso zawo zokwenza ngokwezifiso ithreyi le-acrylic. Lokhu kungenziwa ngocingo, i-imeyili, noma imihlangano yobuso nobuso.

Ingxoxo Yesidingo

Umenzi uqhuba ingxoxo eningiliziwe ngezidingo nekhasimende ukuze aqonde izidingo ezithile zekhasimende, okuhlanganisa nezidingo mayelana nosayizi, ukuma, umsebenzi, ubuningi, isikhathi sokulethwa, njll.

Iseluleko Sobuchwepheshe

Abakhiqizi banikeza izeluleko zobuchwepheshe zobungcweti ngokwezidingo zamakhasimende, okuhlanganisa ukukhethwa kwezinto ze-acrylic, ukuthi kungenzeka yini ukuklama, kanye nezinye izici zesiphakamiso.

Isilinganiso kanye neNkontileka

Umenzi unikeza ikhotheshini eningiliziwe ngokusekelwe ezidingweni zekhasimende kanye nemiphumela yengxoxo bese efinyelela esivumelwaneni sesivumelwano nekhasimende.

Esigabeni sokuhlaziywa kwesidingo kanye nokuxhumana, abakhiqizi be-acrylic badinga ukulalela ngenkuthalo izidingo zamakhasimende, babeke iziphakamiso zobungcweti, futhi balondoloze ukuxhumana kanye nempendulo ngesikhathi esifanele. Ukuqonda okuphelele kanye nokuqonda okunembile kwezidingo zamakhasimende kuzobeka isisekelo esiqinile sezigaba zokuklama nokukhiqiza ezilandelayo, okuqinisekisa ukuthi ithreyi lokugcina le-acrylic elenziwe ngokwezifiso lingahlangabezana ngokugcwele nokulindelwe ngamakhasimende kanye nezidingo zawo.

Uma usebhizinisini, ungase uthande

B) Isigaba Sokuklama

Isigaba sokuklama siyisinyathelo esibalulekile enkambisweni yokwenza ngokwezifiso ithreyi ye-acrylic, ehilela ukwakha uhlelo oluthile lokuklama ithreyi ye-acrylic ngokwezidingo zamakhasimende kanye nezidingo zobuchwepheshe. Nazi izinyathelo ezibalulekile kanye nezinqubo esigabeni sokuklama:

1. Umklamo Wokuqala:

- Ngokwezidingo kanye nemininingwane yobuchwepheshe enikezwe yikhasimende, umenzi wethreyi wenza umklamo wokuqala. Lokhu kuhlanganisa ukunquma usayizi, ukuma, ukubukeka, kanye nezinye izinto eziyisisekelo zethreyi ye-acrylic, kanye nokudweba imidwebo yomklamo wokuqala.

- Cabanga ngendawo yokusetshenziswa kanye nezidingo zethileyi, njengomthamo wokuthwala umthwalo, imodi yokufaka inqwaba, imodi yokuphatha, njll., ukuqinisekisa ukusetshenziswa kanye nokusebenza kahle komklamo.

2. Ukumodela kanye nokubuka ngeso lengqondo kwe-3D:

- Kusetshenziswa isofthiwe yokuklama esizwa yikhompyutha, kwenziwa imodeli ye-3D, futhi umklamo wokuqala uguqulwa ube imodeli ethile ye-3D. Ngakho-ke ngingabonisa ukubukeka okungcono kanye nesakhiwo sethreyi, futhi ngisize amakhasimende ukuba aqonde kangcono ukubukeka komkhiqizo wokugcina.

- Abakhiqizi bangasebenzisa amamodeli e-3D ukuze babonise ngokubonakalayo ukuze amakhasimende akwazi ukubuyekeza umklamo futhi aphakamise izinguquko. Lokhu kusiza ukuqinisekisa ukuthi umklamo uhambisana nokulindelwe kanye nezidingo zekhasimende.

3. Cabanga Ngosayizi, Isimo, Nomsebenzi:

- Esigabeni sokuklama, umenzi udinga ukucabangela usayizi, ukuma, kanye nomsebenzi wethileyi. Usayizi kufanele uhlangabezane nezidingo zamakhasimende kanye nezidingo zokusetshenziswa ezisebenzayo, ukuma kufanele kufanelane nomkhiqizo futhi kube lula ukuwuphatha nokuyibeka, futhi umsebenzi kufanele uhlangabezane nenhloso yokusetshenziswa kanye nezidingo ezikhethekile zethileyi.

- Imininingwane efana nokuphathwa komphetho, isakhiwo esithwala umthwalo, kanye nomklamo wamathileyi ongasheleli kufanele futhi kucatshangelwe ukuqinisekisa ukuzinza, ukuqina, kanye nokuphepha kwamathileyi.

4. Buyekeza futhi Uqinisekise Ngokuphindaphindiwe:

- Ngokwempendulo nemibono yamakhasimende, abakhiqizi benza izinguquko kanye nokulungiswa okudingekayo, kuze kube uhlelo lokugcina lokuklama ukuze bathole ukuqashelwa nokwaneliseka kwamakhasimende.

- Lokhu kungadinga ukuxhumana okuningi kanye nokuguqulwa ukuqinisekisa ukuthi umklamo uhambisana ngqo nokulindelwe yikhasimende nokuthi izici zokusebenziseka kanye nezindleko zokukhiqiza kwangempela zicatshangelwa ngokugcwele.

Ukubaluleka kwesigaba sokuklama ithreyi ye-acrylic akunakunganakwa. Ngokucabangela usayizi, ukuma, kanye nokusebenza ndawonye, abakhiqizi bayakwazi ukuklama amathreyi e-acrylic enziwe ngokwezifiso ahlangabezana nezidingo zamakhasimende. Amathreyi aklanywe ngokucophelela angathuthukisa ukusebenza kahle kwempahla, anciphise ukulahleka, futhi athuthukise isithombe somkhiqizo. Ngakho-ke, kubalulekile ukunaka imininingwane esigabeni sokuklama ukuqinisekisa ukuthi uhlelo lokuklama lunengqondo futhi lungenzeka ukuze kufezwe umphumela omuhle kakhulu wokwenza ngokwezifiso.

C) Ukukhethwa Nokucubungula Izinto

Ukukhethwa nokucubungula izinto kuyingxenye ebalulekile yenqubo yokwenza ngokwezifiso ithreyi le-acrylic, ehilela ukukhethwa kwezinto ezifanele ze-acrylic kanye nokucubungula nokukhiqiza okuhambisanayo. Nansi imininingwane efanele:

1. Izici kanye Nokucatshangelwa Kokukhetha Kwezinto Zokwenziwa ze-Acrylic:

- Ukucaca: I-Acrylic inokukhanya okuhle kakhulu, okwenza kube yinto efanelekile yokubonisa nokubonisa imikhiqizo.

- Ukuqina: I-Acrylic inokumelana okukhulu nokushaqeka nokuguguleka, futhi ingamelana nengcindezi enkulu nokusetshenziswa ezindaweni zokuthutha kanye nezindawo zokugcina impahla.

- Isisindo esilula: Uma kuqhathaniswa nengilazi, izinto ze-acrylic zilula futhi kulula ukuziphatha nokuzisebenzisa.

-

Ingenziwa Ngokwezifiso: I-Acrylic ingacutshungulwa kalula futhi ihlelwe ngokwezifiso ukuze ihlangabezane nezidingo zezimo nobukhulu obuhlukene ngezinqubo ezifana nokushisa, ukusika, ukubhoboza, njalo njalo.

- Avikela uthuli futhi awamelani nokuma: Amathreyi e-Acrylic angaba nezici zokuvikela uthuli kanye nokuma okuma ukuvikela umkhiqizo othulini kanye nogesi ongaguquki.

Uma ukhetha izinto ze-acrylic, kufanele ucabangele izici ezilandelayo:

- Indawo yokusetshenziswa kanye nezidingo zethileyi, okuhlanganisa izinga lokushisa, umswakama, ukuthintana kwamakhemikhali, njll.

- Umthamo wokuthwala umthwalo kanye nezidingo zokuqina kwamathileyi.

- Isabelomali sekhasimende kanye nemikhawulo yezindleko.

2. Inqubo Nobuchwepheshe Bokucubungula Ithreyi Ye-Acrylic:

- Ukusika nokubumba: Ngokwemidwebo yokuklama, ishidi le-acrylic lisikwa libe nesimo nosayizi owufunayo kusetshenziswa umshini wokusika noma ubuchwepheshe bokusika nge-laser.

- Ukwakha i-thermoforming: Ngokufudumeza nokubumba, ishidi le-acrylic elisikiwe lenziwa libe yisimo esithile sethreyi. Lokhu kungenziwa ngesibhamu sokushisa, ipuleti elishisayo, noma imishini yokwenza i-vacuum.

- Ukucutshungulwa kwemigodi nezikhala: Kusetshenziswa umshini wokubhoboza noma ubuchwepheshe bokusika nge-laser, imigodi nezikhala kucutshungulwa epuletini le-acrylic ukuze kube lula ukufaka ithreyi, ukulungisa, noma ezinye izinjongo ezithile.

-

Ukwelashwa kwendawo: Ngokwezidingo, ithreyi le-acrylic liyapholishwa, lihlanzwe, noma liphathwe ngenye indlela ukuze kuthuthukiswe ikhwalithi yokubukeka kanye nokuthinta.

Inqubo yokucubungula idinga ukuqhutshwa ochwepheshe abanolwazi ukuqinisekisa ikhwalithi yokucubungula kanye nokunemba kwethreyi ye-acrylic. Ngesikhathi esifanayo, izinyathelo zokuphepha kufanele zinakwe ngesikhathi sokucubungula ukuqinisekisa ukuphepha kwabaqhubi kanye nokusebenza okuvamile kwemishini.

Ngokukhethwa kwezinto ezifanele kanye namasu okucubungula anembile, abakhiqizi bangakhiqiza amathreyi e-acrylic enziwe ngokwezifiso asezingeni eliphezulu ahlangabezana nezidingo zamakhasimende. Ngokusebenza okuhle kakhulu nokuthembeka, la mathreyi ahlinzeka ngesisombululo esisebenzayo sezinqubo zezokuthutha kanye nezindawo zokugcina impahla.

Siyakwamukela efektri yethu yamathileyi e-acrylic angokwezifiso! Sinikeza izinsizakalo zokwenza ngokwezifiso ezihamba phambili embonini, ngakho-ke noma ngabe udinga ukwenza ngokwezifiso izinto zakho noma ufuna ukudala umkhiqizo oyingqayizivele womcimbi wenkampani, singahlangabezana nezidingo zakho. Kusukela ekuklanyweni kuya ekukhiqizweni, ithimba lethu lochwepheshe lizolwela ukudala amathileyi e-acrylic akhethekile kuwe, ukuze uzizwe unesipiliyoni esiyingqayizivele kukho konke ukusetshenziswa.

D) Ukukhiqizwa Nokuhlanganiswa

Inqubo yokukhiqiza kanye nemininingwane yobuchwepheshe yamathileyi e-acrylic kuyisihluthulelo sokuqinisekisa ikhwalithi yomkhiqizo wokugcina. Nansi imininingwane efanele:

1. Inqubo Yokukhiqiza kanye Nemininingwane Yobuchwepheshe:

- Lungisa izinto zokwakha: Lungisa amashidi e-acrylic adingekayo kanye nezinye izingxenye ngokuya ngosayizi kanye nezidingo zesimo ezinqunywe umklamo.

- Ukusika nokubumba: Kusetshenziswa umshini wokusika noma ubuchwepheshe bokusika nge-laser, ishidi le-acrylic lisikwa ngokwezidingo zomklamo, bese inqubo yokushisa isetshenziswa ukulibumba libe yithreyi.

- Imigodi nezikhala zemishini: Kusetshenziswa umshini wokubhoboza noma ubuchwepheshe bokusika nge-laser, imigodi nezikhala ziyacutshungulwa ephepheni le-acrylic ukuze kufakwe ithreyi, kulungiswe, noma kwezinye izinjongo ezithile.

- Ukwelashwa kwendawo: Ukupholisha, ukusantisa noma okunye ukwelashwa kwendawo yepuleti le-acrylic ukuze kuthuthukiswe ikhwalithi yokubukeka kanye nokuthinta.

- Ukuhlanganiswa: Ngokwezidingo zomklamo, ipuleti le-acrylic nezinye izingxenye ziyahlanganiswa, njengezingqimba zokuxhuma, izikulufo zokulungisa, njll., ukuqinisekisa ukuzinza kwesakhiwo kanye nobuqotho bokusebenza kwethileyi.

2. Ukulawulwa Kwekhwalithi Nokuhlolwa Komhlangano:

-

Enqubweni yokukhiqiza, ukulawulwa kwekhwalithi kubalulekile. Abakhiqizi kufanele bamise amazinga okulawula ikhwalithi aqinile futhi benze ukuhlolwa nokuhlolwa ukuqinisekisa ikhwalithi nokunemba kwesixhumanisi ngasinye sokukhiqiza.

- Esigabeni sokusika nokwakheka, kuyadingeka ukuqinisekisa ukuthi usayizi, ukuma, kanye ne-engela yeshidi le-acrylic kuyahlangabezana nezidingo zomklamo ukuze kugwenywe ukuphambuka kosayizi noma ukuguquguquka okubi.

- Uma ulungisa imigodi nezikhala, hlola ukuthi indawo yazo nosayizi wazo kunembile yini, futhi uqinisekise ukuthi imigodi nezikhala zibushelelezi futhi zihambisana kahle.

-

Esigabeni sokwelashwa kobuso, kwenziwa ukupholisha nokuhlanza okwanele ukuqinisekisa ukuthi ubuso bethileyi bubushelelezi futhi abuklwebheki, futhi noma yiluphi uthuli noma ukungcola kuyasuswa.

-

Enqubweni yokuhlanganisa, ukulingana kanye nokuqina kokuxhumeka kwengxenye ngayinye kufanele kuhlolwe ngokucophelela ukuqinisekisa ukuthi isakhiwo sethreyi siqinile futhi siyasebenza.

Ngokulawula ikhwalithi okuqinile kanye nokuhlolwa kokuhlanganiswa, abakhiqizi bangaqinisekisa ukuthi azikho izinkinga zekhwalithi noma amaphutha akhona ngesikhathi sokukhiqizwa kwamathileyi e-acrylic. Lokhu kusiza ukuhlinzeka ngemikhiqizo yethileyi esezingeni eliphezulu nethembekile ehlangabezana nezidingo zamakhasimende futhi iqinisekise ukuthembeka nokuqina ezindaweni zokuthutha kanye nezindawo zokugcina impahla.

Ikesi Lethreyi Le-Acrylic Elingokwezifiso

Isifinyezo

Leli phepha lixoxa ngenqubo yokwenziwa nokuhlanganiswa kwamathileyi e-acrylic, ligcizelela ukubaluleka kokulawulwa kwekhwalithi nokuhlolwa kokuhlanganiswa ngesikhathi senqubo yokwenziwa. Ngokulawulwa kwekhwalithi okuqinile nokuhlolwa kokuhlanganiswa, abakhiqizi bangaqinisekisa ukuthi azikho izinkinga zekhwalithi noma amaphutha ayenzekayo ngesikhathi sokukhiqizwa kwamathileyi e-acrylic, ngaleyo ndlela banikeze imikhiqizo yethileyi esezingeni eliphezulu nethembekile.

Inqubo Yokwenza Ngokwezifiso Ithreyi Le-Acrylic Inezinzuzo Ezilandelayo:

- Ukwenza Ngokwezifiso: Amathreyi e-Acrylic angenziwa ngokwezifiso ngokwezidingo zamakhasimende kanye nezidingo zawo, okuhlanganisa usayizi, ukuma, umsebenzi, kanye nokubukeka. Lokhu kwenza amathreyi e-acrylic ahlangabezane nezidingo ezithile zezimboni ezahlukene kanye nezinhlelo zokusebenza, okuhlinzeka ngezixazululo ezenzelwe wena.

- Ilula Futhi Ihlala Isikhathi Eside: Izinto ze-Acrylic zinobukhulu obuphansi, okwenza amathreyi e-acrylic abe lula kakhulu, futhi kube lula ukuwaphatha nokusebenza. Ngesikhathi esifanayo, izinto ze-acrylic nazo ziqinile kakhulu futhi zingamelana nemithwalo esindayo kanye nokumelana nomthelela, okuqinisekisa ukusetshenziswa kwesikhathi eside kwamathreyi ezindaweni zokuthutha kanye nokugcina.

- Ukucaca kanye nomphumela wokubonisa: Ithreyi le-Acrylic linokukhanya okuhle, lingabonisa imikhiqizo ngokucacile, lithuthukise umphumela wokubonisa kanye nokukhanga kwemikhiqizo. Lokhu kubaluleke kakhulu kubathengisi kanye nemboni yokubonisa ukuze kudonswe ukunaka kwabathengi ngempumelelo.

- Ukusebenza okulwa nokungaguquguquki kanye nokuvikela uthuli: izinto ze-acrylic zingaphathwa nge-anti-static ukugwema umonakalo emikhiqizweni nasezintweni ze-elekthronikhi ezibangelwa ukuphazamiseka kwe-electrostatic. Ngaphezu kwalokho, ubuso obubushelelezi bethreyi ye-acrylic bunciphisa nokuqongelela kothuli nokungcola, okugcina ukuhlanzeka komkhiqizo.

Inqubo Yokwenza Ngokwezifiso Ithreyi Le-Acrylic Inamathuba Emakethe Ebanzi:

- Imboni Yezokuthutha kanye Nezindawo Zokugcina Izinto: Amathreyi e-Acrylic asetshenziswa kabanzi embonini yezokuthutha kanye nezindawo zokugcina izinto, okungathuthukisa ukusebenza kahle kwezokuthutha kanye nokuphathwa kokugcinwa kwezimpahla. Ngokukhula kwesidingo sezokuthutha emhlabeni wonke, isidingo semakethe samathreyi e-acrylic sizoqhubeka nokukhula.

- Imboni Yokuthengisa Nokubonisa: Amathreyi e-Acrylic anganikeza umphumela ocacile wokubonisa umkhiqizo, okwenza asetshenziswe kabanzi embonini yokuthengisa nokubonisa. Njengoba ukuncintisana okwandayo kokuthengisa kanye nokugcizelela kwabathengi ekubukekeni komkhiqizo, isidingo semakethe samathreyi e-acrylic sizoqhubeka nokukhula.

- Imboni ye-elekthronikhi kanye ne-semiconductor: Izakhiwo ezilwa nokungaguquguquki zamathileyi e-acrylic ziwenza abe ukukhetha okuhle embonini ye-elekthronikhi kanye ne-semiconductor. Ngokuthuthuka okuqhubekayo kwemikhiqizo ye-elekthronikhi kanye nokwanda kwesidingo, amathileyi e-acrylic emakethe yemboni amathuba abanzi kakhulu.

Ngamafuphi, inqubo yokwenza ngokwezifiso ithreyi le-acrylic inezinzuzo eziningi futhi inamathuba amaningi emakethe embonini yezokuthutha, yokugcina impahla, yokuthengisa, yokubonisa, ye-elekthronikhi, kanye neye-semiconductor. Abakhiqizi bangahlangabezana nezidingo zamakhasimende ngezinqubo zokukhiqiza zobungcweti kanye nokulawula ikhwalithi, futhi banikeze imikhiqizo yethreyi le-acrylic esezingeni eliphezulu, eyenzelwe wena.

Isikhathi sokuthunyelwe: Agasti-29-2023